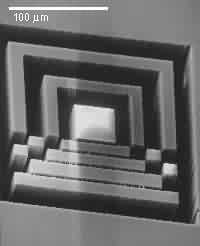

Micromachining

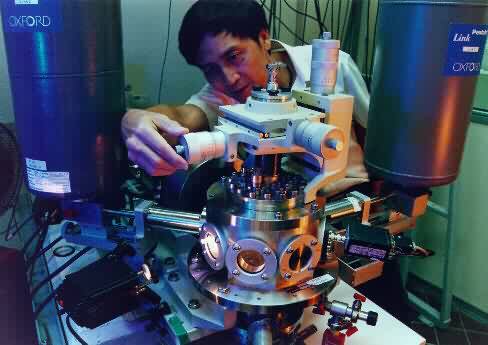

The Nuclear Microscopy Group at the National University

of Singapore, using an OM2000 endstation, have shown

that a focused high energy (eg 2MeV) proton beam is

ideally suited to precise 3 dimensional micromachining.

By scanning the proton beam over a resist material in

a predetermined pattern, specific shapes can be produced

in the resist when the resist is treated with a suitable

developer.

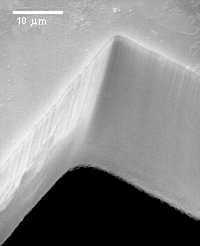

The advantages of this technique (Proton Micromachining,

or Deep Ion Beam Lithography - DIBL), is that the process

is truly three dimensional: The precise depth of

machining is determined by the energy of the proton

beam, eg a 2 MeV proton beam will expose to 60 microns

depth in PMMA. High aspect ratios approaching 100,

and submicron structures have been achieved.

The potential of this technique in the new fields

of MEMS (Micro-ElectroMechanical Systems) and

micromachining is extremely high.

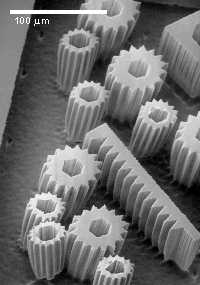

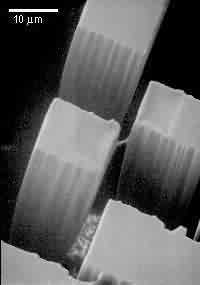

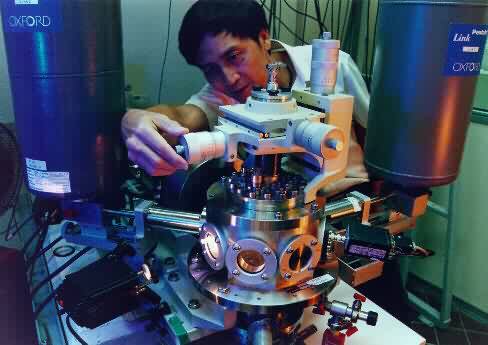

The pictures below show typical examples of

the micromachining technique.

All of these examples have been made

at the National University of Singapore

Scanning Proton Microprobe Facility

using an Oxford Microbeams

OM2000 endstage.